Visualise, standardise, optimise

Years ago, via the brilliant Dan Terhorst-North, I discovered the phrase “Visualise, standardise, optimise” as a way to describe a structured approach to business or process improvement. It’s been tremendously valuable in my work to help teams and organisations improve what they do. It’s a nice corollary to the GROW model.

When faced with a sub-optimal situation or process, it’s always tempting to jump straight in and start making changes immediately trying to introduce routines, habits, and other supposed improvements. But without first understanding the as-is state and ensuring this state is relatively stable, it’s pointless to start suggesting or worse, trying to implement change.

The only exception to this is when the as-is state is so chaotic and difficult to understand that any change might be an improvement or at least provide some clues about how the system works. In this case, the model of act-sense-respond (AKA “poke it and see”) can be useful.

In most cases the following process holds up well.

1. Visualise (Understand the “as-is”)

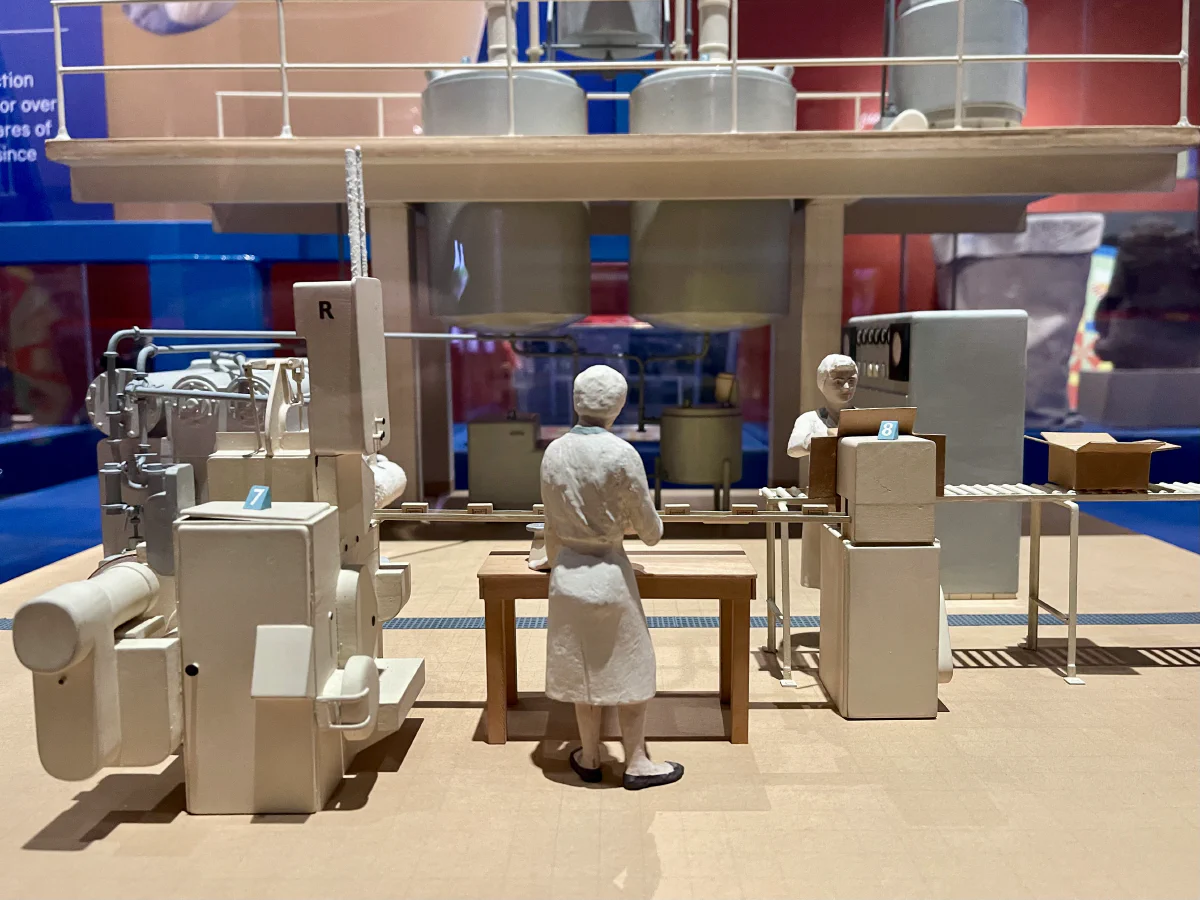

Create transparency and shared understanding of the current reality by identifying and mapping out all the existing workflows, stakeholders, customers, suppliers, inputs, and outputs. This may involve interviewing stakeholders, creating flow-charts, value stream maps (VSM), models, video walk-throughs, and more.

This helps to make complex and often invisible, processes visible and well understood. Identify all the steps, decision points, responsibilities, and existing inefficiencies or bottlenecks, for better or worse.

This ensures we all have the same idea of how things work today regardless of whether they “should” work this way. It improves communication and clarity across all teams, individuals, and stakeholders as everyone refers to the same set of artefacts and has the same opportunity to contribute or make adjustments.

2. Standardise (or “Stabilise”)

Once we understand how we think we’re doing things, we want to ensure we do things this way as consistently as possible. This phase is about minimising variation, instability, and errors while maximising predictability. This is also the time to identify key metrics and establish baseline values. These will enable you to easily measure the impact of subsequent improvements via OKRs.

Various tools can be helpful here such as clear work instructions, routines, standard operating procedures, templates, documented patterns, roles & responsibilities, RACI matrices, team charters, visual feedback & control systems including Kanban boards, or the 5s method.

3. Optimise (Enhance and Refine)

With a stable, standard, repeatable process in place, we can shift the focus to continuous improvement and enhancement. If we rush to optimise without first standardising, we can create chaos as improvements in one area can negatively impact an interconnected non-standardised process.

Actions here include retrospecting, proposing changes, running experiments, automation, re-routing workflows to remove bottlenecks and introducing new control mechanisms. This phase may also include revisiting the governance of key processes. Who are the main stakeholders? What can they do differently? How can key meetings be adjusted to provide more useful steer and intervention when required?

This phase is what makes the process more efficient, effective, and adaptable to changing conditions (e.g. market changes, new tech, etc). It reduces waste, improves overall performance, and improves sustainability. Optimisation is an ongoing, cyclical process of monitoring and refining the new standard.

Use it anywhere & everywhere

This process can be applied in various places and levels throughout an organisation. Use it to describe something as tactical and specific as deploying a piece of software or even broad and non-technical topics such as hiring talent or securing funding.